Dock Seals: A Complete Overview

Loading docks are vital to supply chain efficiency. But with every truck that backs up to a warehouse, there’s a potential for energy loss, safety hazards, and contamination. That’s where a dock seal makes all the difference.

Dock seals create a tight barrier between the dock door and the trailer, helping businesses minimize air exchange, protect goods, and improve workplace safety. In this complete overview, we’ll explain what dock seals are, how they work, and why they’re essential for modern logistics and warehousing.

What Is a Dock Seal?

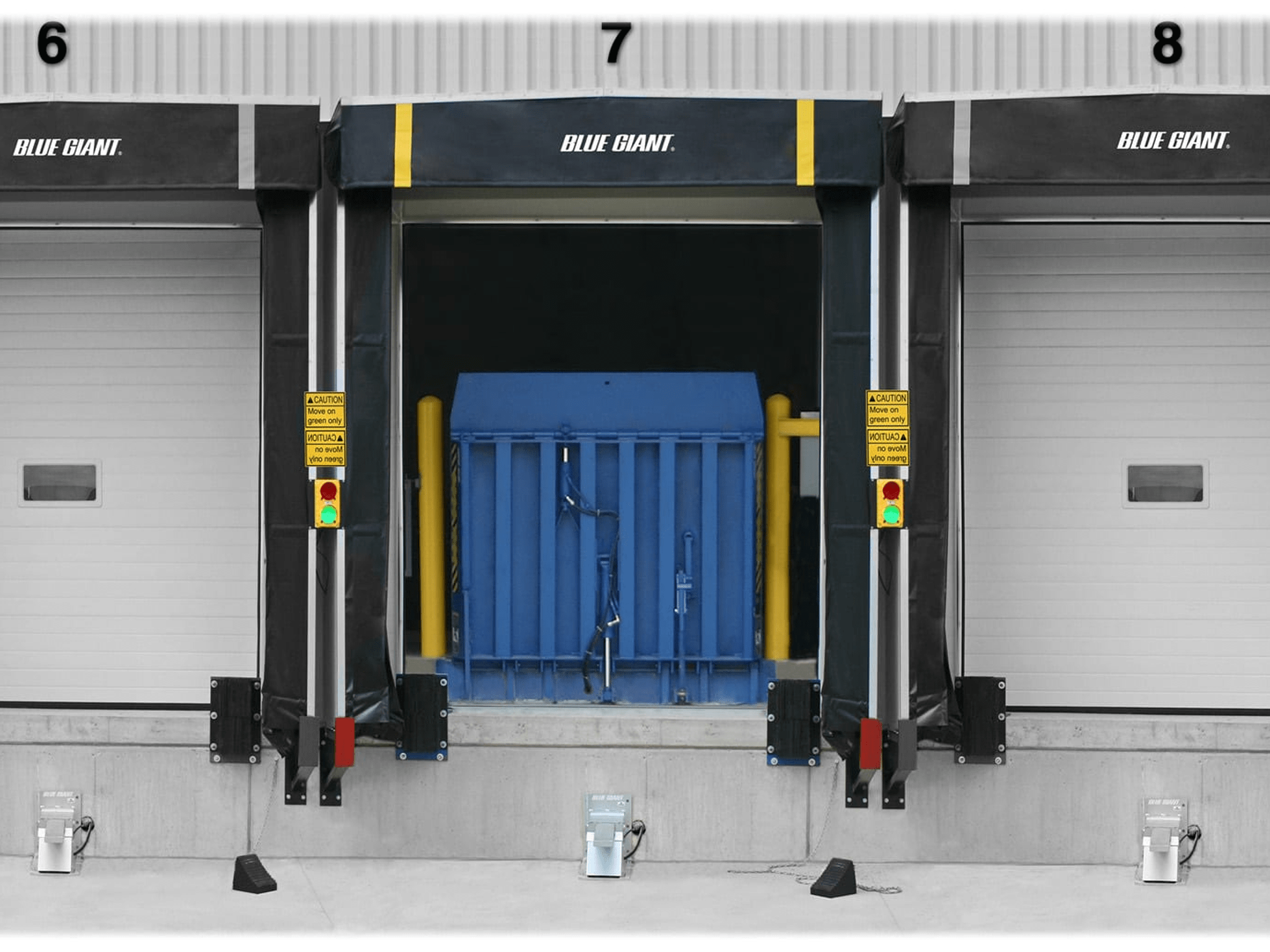

A dock seal is a padded enclosure installed around the perimeter of a loading dock door. When a trailer backs into the dock, it compresses the foam pads of the seal, forming a tight seal that blocks external air, dust, pests, and moisture from entering the building.

Dock seals are typically made from heavy-duty fabric with internal foam cores. They are commonly used in temperature-controlled environments like cold storage, food distribution centers, and manufacturing facilities that handle sensitive products.

Key Benefits of Dock Seals

Investing in a high-quality dock seal offers several operational and financial advantages:

1. Improved Energy Efficiency

Dock seals reduce the amount of air that escapes during loading and unloading, helping maintain interior temperatures. This is crucial in climate-controlled environments where heating or cooling costs are significant.

2. Enhanced Safety

By sealing the gap between the trailer and the dock door, dock seals reduce the risk of slips, trips, or exposure to harsh weather conditions for employees working on the dock.

3. Protection Against Contaminants

Seals help prevent dust, insects, rainwater, and other contaminants from entering the warehouse, which is vital in clean environments like pharmaceutical or food processing facilities.

4. Reduced Equipment Strain

Maintaining stable internal temperatures reduces wear and tear on HVAC and refrigeration systems, extending equipment life and reducing maintenance costs.

5. Better Compliance

For industries governed by cleanliness and temperature standards, dock seals help facilities remain compliant with health and safety regulations.

Types of Dock Seals

Dock seals come in various styles to fit different facility needs and trailer sizes:

- Compression Foam Seals: The most common type, offering a tight seal as trailers back into them.

- Head Pad Seals: Provide a seal at the top of the trailer, ideal for facilities with consistent trailer heights.

- Adjustable Head Curtains: Accommodate a variety of trailer heights while sealing the top gap effectively.

- Full Perimeter Seals: Enclose all sides of the dock door for maximum protection and insulation.

The choice of seal depends on factors like the frequency of use, the size and type of trucks, and whether the facility is temperature-sensitive.

Dock Seal vs. Dock Shelter: What’s the Difference?

While often confused, dock seals and dock shelters serve different functions. A dock seal creates a tighter, foam-compressed seal for climate control, while a dock shelter provides a flexible enclosure that fits a wider variety of trailer sizes. Shelters allow more trailer movement but provide a slightly looser seal.

If your facility requires airtight insulation and handles similar truck sizes, a dock seal is likely the better choice. For operations with diverse trailer sizes, a shelter may offer more flexibility.

Installation & Maintenance Tips

Proper installation ensures maximum performance. Dock seals must be installed flush with the dock door and aligned to the average trailer height and width used. It’s also essential to:

- Inspect seals regularly for tears or worn fabric

- Clean the surface to prevent mold or mildew buildup

- Replace foam cores if compression becomes ineffective

Regular maintenance extends the life of your dock seal and ensures continued protection and efficiency.

Final Thoughts

A dock seal is a small investment that delivers big returns in energy efficiency, cleanliness, employee safety, and operational performance. Whether you’re running a cold storage warehouse, food distribution center, or general logistics facility, sealing the gap between your building and incoming trailers is critical.

If you’re considering upgrading your dock setup or building a new facility, choose a dock seal solution that matches your specific dock traffic, climate control needs, and regulatory requirements.

Looking to find the right dock seal for your warehouse? Reach out to experienced professionals who can help you choose and install the ideal solution for your operation.